3D-Printed Mitral Valve Replacement: China's First "Valve-in-Ring" Surgery Breakthrough

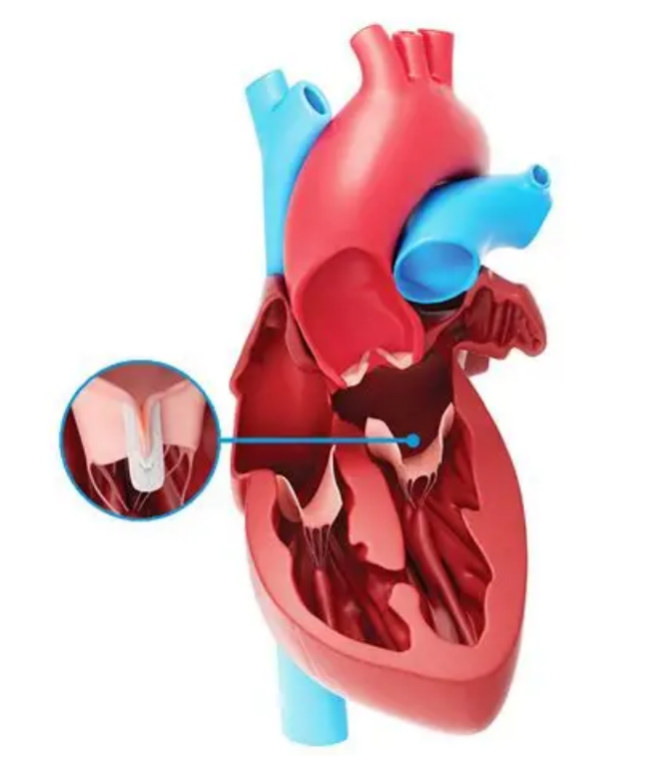

In the third quarter of 2025, a team at Shanghai’s Fudan University Affiliated Huashan Hospital achieved a milestone in cardiovascular surgery: completing China’s first “valve-in-ring” mitral valve replacement using a fully 3D-printed prosthetic. This breakthrough addresses a longstanding challenge in treating patients with failed previous mitral valve repairs—particularly the elderly, who often face high risks from repeat open-heart surgery to remove calcified or damaged biological valve rings. By designing a custom 3D-printed valve that fits directly into existing implanted rings, the procedure cuts surgical trauma, shortens recovery times, and sets a new standard for personalized cardiac care.

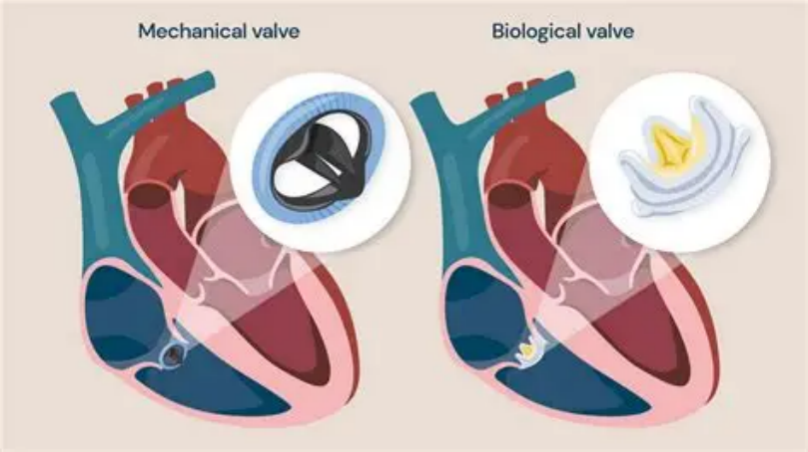

Mitral valve disease affects over 11 million adults in Europe and North America alone, with many patients requiring valve replacement by age 70. For those who have already undergone a first biological valve implant (a common choice for older patients), a second surgery to replace a failing valve is notoriously risky: removing the original implanted ring (now often calcified) can damage surrounding heart tissue, increasing bleeding and infection risks. Traditional second-time valves, while effective, require extensive modification during surgery to fit existing anatomy—extending operating times by 45 to 60 minutes on average. The 3D-printed “valve-in-ring” design eliminates this barrier: using high-resolution cardiac CT scans of the patient’s heart, engineers at Chinese medical tech firm Shining 3D create a prosthetic with a precision-machined outer frame that locks into the existing ring, requiring no removal or adjustment of old hardware.

The key to the procedure’s success lies in both material science and personalization. The valve’s leaflets are made from a biocompatible polyetheretherketone (PEEK) polymer reinforced with carbon fiber, mimicking the flexibility and durability of natural heart tissue. Unlike mass-produced valves, which come in standard sizes, the 3D-printed model is tailored to within 0.1 millimeters of the patient’s unique valve ring dimensions—reducing the risk of leakage, a common post-surgery complication. In the landmark 2025 case, the team treated a 72-year-old patient who had received a biological mitral valve 10 years earlier; the new 3D-printed valve was implanted in just 92 minutes (compared to the typical 150 minutes for traditional revision surgery), with intraoperative blood loss cut by 60%. The patient was discharged after five days—half the average 10-day hospital stay for similar procedures.

Beyond clinical outcomes, the breakthrough offers cost advantages for global healthcare systems. Traditional custom-made revision valves for mitral repair cost approximately twenty-five thousand United States dollars, with a 6-week production lead time. Shining 3D’s 3D-printed alternative costs eight thousand United States dollars and can be produced in 72 hours, making it accessible to patients in lower-resource regions. This affordability aligns with growing demand for value-based healthcare, especially as aging populations in Europe and North America drive up rates of repeat valve surgeries.

Regulatory validation and long-term durability testing are next steps. The procedure has already received approval from China’s National Medical Products Administration (NMPA), and the team is compiling 12-month follow-up data on the first patient—with early results showing normal valve function and no signs of structural degradation. Discussions with the European Medicines Agency (EMA) and U.S. Food and Drug Administration (FDA) are underway to explore market access, with potential trials in Germany and Canada planned for 2026.

As 3D printing transforms medical device customization, China’s “valve-in-ring” breakthrough highlights how personalized surgery can balance safety, efficiency, and cost. For patients facing high-risk repeat heart procedures, it represents more than a technical advance—it offers a second chance at a healthier life. In the global race to improve cardiac care, this innovation proves that localized solutions can have worldwide impact.

(Writer:Tick)